BENTELER Automotive in the Czech Republic

STRÁŽ NAD NISOU

The first Czech plant of BENTELER Automotive opened in 1995 in Stráž nad Nisou. It is the smallest BENTELER plant in the Czech Republic, and most employees have been working there for a number of years. That results in a very personal atmosphere where all colleagues know each other and collaborate closely in their projects. Production focuses on the welding of chassis parts. Stráž was the first plant to start the fully automated production of rear axles with torsion beams.

CHRASTAVA

The plant in Chrastava was built in 1999 and is one of the most progressive and successful plants of BENTELER Automotive worldwide. It produces chassis and structures parts, using technologies such as (hydro) forming, bending, lasers and welding. It is also specialized in assembling rear axle modules. The plant serves most European car manufacturers, among them German premium brands.

Chrastava is also home of the BENTELER Headquarters for region Northern Europe. It houses various corporate departments, such as Finance, Human Resources, Procurement, Sales, Development, Materials and Technical Planning, Quality and Maintenance.

JABLONEC

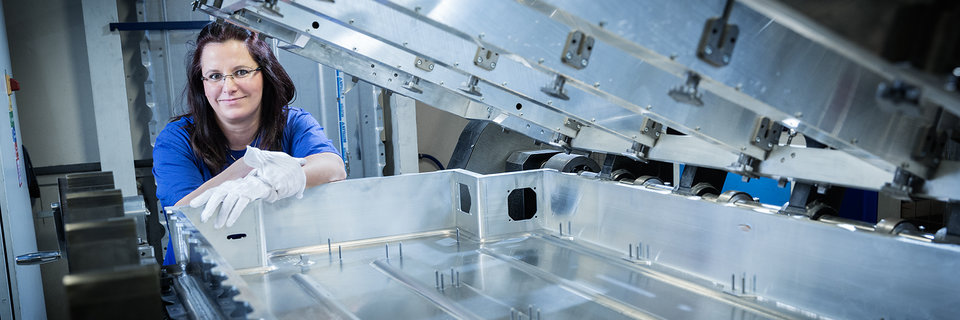

The Jablonec plant, which opened in 2006 in Jablonec nad Nisou, mainly produces steel and aluminum structures, frame chassis for motorcycles and custom-made spare parts. It closely cooperates with the BENTELER Technical Development department and is shifting its production focus to lightweight solution parts. Lighter vehicles need less gasoline, so this development will ultimately make a contribution to sustainability. The BENTELER development and design center for chassis and structural parts is also located here.

RUMBURK

The fourth Czech plant is located in Rumburk. With more than 33,000 m2 of production and logistics space and almost 1,000 employees, it is one of the largest plants of BENTELER Automotive. It serves European carmakers with a large selection of services, covering the complete manufacturing process for the respective parts. Production technology includes cold and hot stamping, welding, laser cutting, machining and painting. Manufactured parts are assembled on site.

MALACKY

The plant in Malacky became a member of the BENTELER family in 2009. With 360 employees, it produces about 4.5 million pieces each year. BENTELER in Malacky is the only automotive parts manufacturer in Slovakia that uses hot forming technology. Other innovative solutions include aluminum and steel welding in protective atmospheres, resistant welding as well as advanced 3D laser cutting technology.

KLÁŠTEREC

The newest and most modern plant in the Czech Republic was built in the industrial zone in Klášterec nad Ohří in 2017. The production technologies include cold and hot stamping, welding and 3D laser cutting. Emphasis is placed on the high degree of automation within each process.

LIBEREC

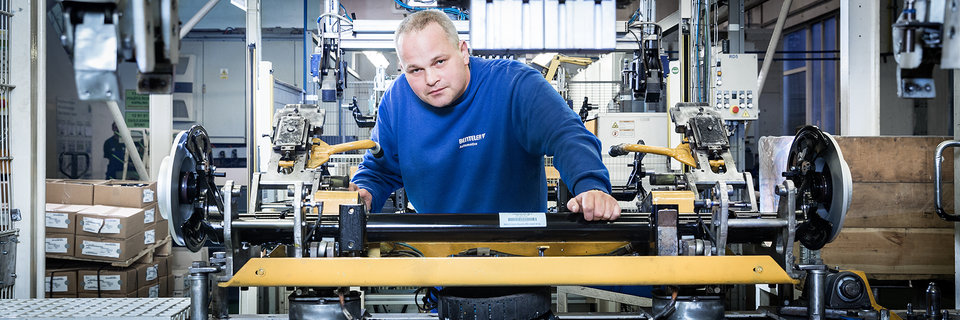

The focus of the plant in Liberec (BENTELER Maschinenbau) lies in the construction and production of machines and robots for the automobile industry. Each machine is custom-made and will be produced exactly to customers’ specifications. Employees of the plant develop, construct and produce machines and lines, assemble machines, construct switchboards as well as program and commission robots.